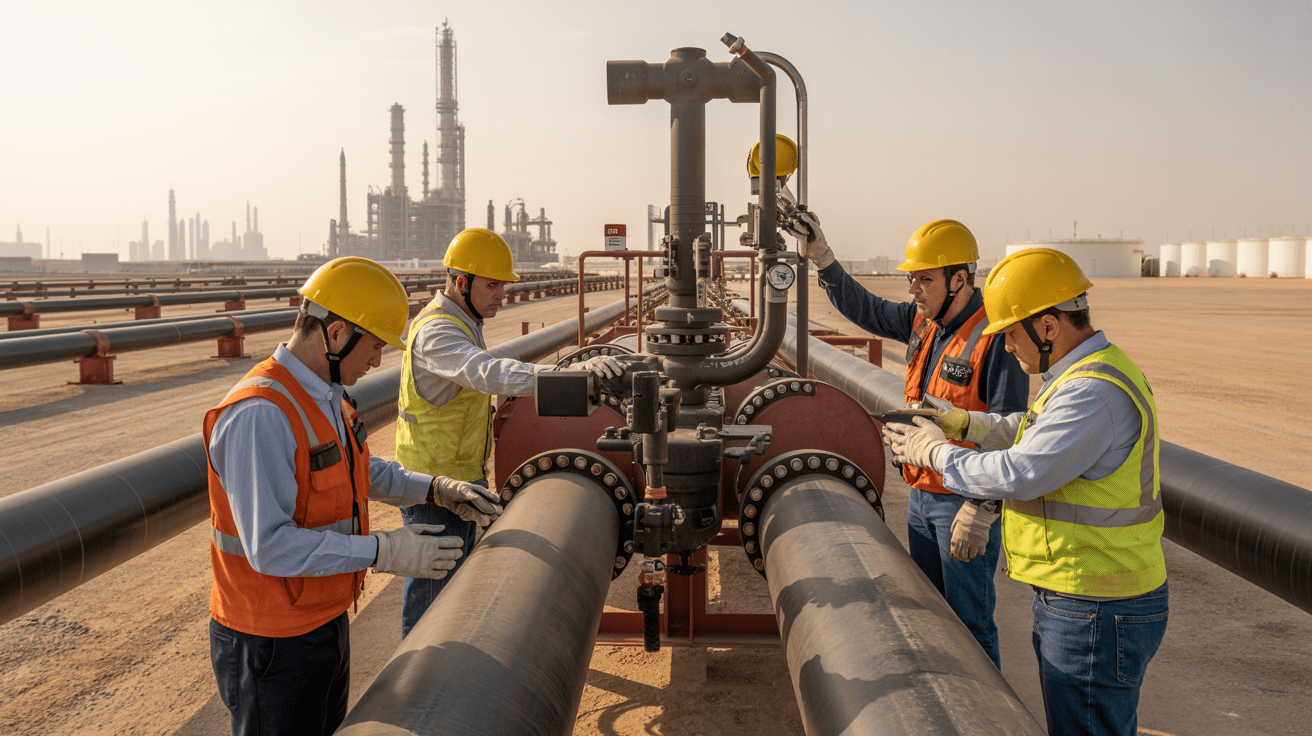

Pipeline operators in the UAE rely on dependable systems to ensure products flow smoothly. A reliable pig launcher & receiver manufacturer is essential for pipeline safety. They guard against blockages, corrosion, and expensive downtime. These systems help ensure safe operations, even in the harshest conditions. They also help maintain long-term integrity. This is key for oil, gas, and industrial networks.

In the UAE, demand for advanced solutions continues to grow. Many facilities depend on top-notch piping fabrication. They also need skilled static equipment manufacturers to keep operations running smoothly. Therefore, choosing the right partner is crucial. In this guide, you’ll discover how pig launchers and receivers operate. You’ll see why they matter. Choosing the right manufacturer can boost pipeline reliability.

What is the Role of a Pig Launcher & Receiver Manufacturer

A trusted maker of Pig Launchers and Receivers produces key tools for cleaning, inspecting, and maintaining pipelines. These systems send and receive pipeline “pigs.” These pigs travel through pipes. They clear debris, check wall thickness, and find early signs of damage. When designed well, they help operators prevent failures before they occur.

Launchers and receivers serve as access points for inserting and removing pigs. However, these systems must be engineered with extreme precision. High pressure, varying temperatures, and challenging conditions call for a manufacturer with strong technical knowledge and industry experience. As a result, operators gain confidence in long-term performance and safety.

Manufacturers work closely with piping fabrication teams. This helps ensure every component fits perfectly in the pipeline network. With good integration, the whole system runs smoothly. This lowers the chance of operational disruptions.

Why Quality Piping Fabrication Matters for Pipeline Efficiency

High-quality piping fabrication is essential for reliable pigging operations. Every pipeline relies on durable joints, proper alignment, and consistent material strength. However, even small fabrication errors can lead to serious issues. Misaligned pipes may restrict pig movement. Weak welds may fail under pressure. Poor material selection may cause corrosion.

To avoid these problems, piping fabrication teams follow strict quality standards. They use advanced welding processes, certified materials, and precise measurements. These practices help maintain a clear and safe path for pigs traveling through the pipeline.

In the UAE, fabrication experts often work alongside pig launcher and receiver engineers. This collaboration helps match equipment specifications with actual pipeline layouts. Therefore, operators receive systems designed to deliver long-lasting, efficient performance.

How Static Equipment Manufacturers Support Pipeline Reliability

A skilled static equipment manufacturer is key to designing pressure vessels and chambers. This is important for pig launchers and receivers. These components must withstand extreme internal forces. They must also resist corrosion caused by different fluids, chemicals, and environmental conditions.

Manufacturers use advanced design standards and international codes to ensure safety. For instance, they might use ASME, API, or ISO guidelines based on the pipeline needs. By following these guidelines, they deliver equipment that performs reliably under stress.

Additionally, static equipment manufacturers help operators optimize space, weight, and installation planning. The engineering team ensures that all launchers and receivers fit snugly in the pipeline system. As a result, the entire system becomes more stable and reliable.

What are the Key Benefits of High-Quality Pig Launchers and Receivers

Reliable pigging systems offer several advantages. Each benefit contributes to stronger, safer, and more efficient pipeline operations.

1. Enhanced Flow Efficiency

Pigs remove built-up debris, scale, wax, and residue. This cleaning process improves flow and reduces pressure drops. Therefore, operators experience better performance without increasing energy consumption.

2. Early Defect Detection

Inspection pigs detect cracks, corrosion, and wall thinning. These findings allow maintenance teams to address issues early. As a result, they can prevent leaks, failures, and unplanned outages.

3. Reduced Operational Downtime

Well-engineered launchers and receivers make pigging faster and safer. Efficient maintenance reduces downtime and boosts productivity.

4. Improved Safety

Quality design minimizes risks during opening, closing, and pressurizing activities. Manufacturers often integrate safety valves, interlocks, and pressure monitoring systems.

5. Long-Term Cost Savings

Prevention always costs less than repair. Consistent pigging extends pipeline lifespan and reduces costly emergency interventions.

How to Choose the Right Pig Launcher & Receiver Manufacturer in the UAE

Selecting the right manufacturing partner directly impacts pipeline reliability. Here are the factors operators should consider:

Technical Expertise

Experienced manufacturers understand complex pipeline systems. They design equipment that meets both operational and regulatory requirements.

Material Quality

The best manufacturers use certified materials designed to withstand high pressure and corrosion. High-grade steel and top-tier coatings extend the equipment’s lifespan.

Integration With Piping Fabrication

Manufacturers that collaborate with fabrication teams achieve better fits and easier installations. This reduces misalignment and improves pig movement.

Support From a Static Equipment Manufacturer

Complete engineering support ensures every system is safe, strong, and made to last.

Customization Options

Every pipeline network is unique. Custom-built systems offer better performance and improved reliability.

How These Systems Improve Overall Pipeline Reliability

Pig launchers and receivers help maintain consistent pipeline health. They provide access for cleaning and inspection without the need for major disassembly. This reduces maintenance time and improves operational flow.

Additionally, these systems protect pipelines from internal corrosion. Clean inner surfaces ensure smoother flow and reduce stress on pumps and compressors. Regular pigging cycles help ensure compliance with regulations. This is crucial in the UAE’s energy sector.

Reliable launchers and receivers also support faster responses to unexpected issues. When problems arise, operators can deploy inspection pigs quickly. Therefore, potential failures can be analyzed and resolved before they escalate.

Final Thoughts

A reliable pig launcher & receiver manufacturer is key for smooth pipeline operations in the UAE.

A reliable system has three key elements:

- Good design

- Solid support from the maker

- Accurate piping fabrication

When these elements collaborate, operators gain cleaner pipelines, a safer environment, and lower long-term costs.

Investing in advanced pigging systems today means a stronger, more efficient pipeline tomorrow.

Choose BERG Industries for precision-engineered pipeline solutions you can trust. Our expert team delivers reliable pig launchers, receivers, and fabrication support. Partner with us today and strengthen your pipeline performance.

FAQs

Why are pig launchers and receivers important for pipeline reliability?

These systems allow regular cleaning and inspection without shutting down operations. As a result, they reduce corrosion, improve flow efficiency, and help detect early defects before major issues occur.

How does piping fabrication affect pigging performance?

Accurate piping fabrication ensures smooth pig movement through the entire pipeline. Proper alignment, quality welds, and durable materials help prevent blockages and protect the integrity of the pigging process.

What role does a static equipment manufacturer play in pigging systems?

A static equipment manufacturer designs the pressure vessels and chambers used in pig launchers and receivers. Their expertise ensures each system withstands high pressure, harsh conditions, and long-term operational demands.