Modular construction is transforming the UAE’s skyline. Today, businesses want speed, precision, and reliable performance. That demand makes a modular buildings manufacturer in UAE more essential than ever. The region also relies on advanced structural steel fabricators in the UAE to support fast-growing industries. As a result, the UAE now leads the Gulf in modular technical buildings and high-performance steel structures.

This guide explores how modular buildings are designed, built, and delivered. It also shows how they compare to traditional construction and why the UAE is the perfect hub for innovation.

How a Modular Buildings Manufacturer in the UAE Transforms a Concept into Reality

Modern modular construction begins long before a single wall is built. A top modular buildings manufacturer in the UAE starts each project with precision planning. This early stage sets the tone for quality, performance, and durability.

Design Engineering: Where Creativity Meets Purpose

Experienced engineers create detailed 3D models that show size, load capacity, building utilities, and finishing requirements. These models allow clients to preview the final design. Early design planning reduces errors, lowers waste, and improves cost control. This is one reason businesses prefer modular buildings over conventional structures.

Material Selection: Ensuring Strength and Sustainability

The UAE faces intense heat, humidity, and corrosive conditions. Therefore, superior materials are essential. Manufacturers use corrosion-resistant steel, insulated sandwich panels, and fire-rated assemblies to ensure long-term performance. High-quality materials also support rapid installation while maintaining structural integrity.

What Is The Role of Structural Steel Fabricators in the UAE in Modular Construction

Modular units rely on strong steel frames. That frame must handle heavy loads, vibration, and environmental stress. Skilled structural steel fabricators in UAE shape, cut, weld, and test steel components to meet international standards.

These fabricators use CNC machinery, robotic welding, and automated cutting systems. As a result, every module frame fits together with exact precision. Furthermore, advanced fabrication speeds up production while keeping safety at the highest level.

How Modules Are Built with Speed and Accuracy

Once design and steel framing are ready, manufacturers start assembly. UAE factories follow a streamlined process that mirrors automotive production lines.

1. Frame Fabrication and Welding

Each module begins as a steel skeleton. Welders and automated machines assemble beams, columns, and floor bases. Strict testing ensures each frame meets load and seismic requirements.

2. Mechanical, Electrical & Plumbing Integration

Technicians install MEP systems directly into the module frame. This includes wiring, breakers, HVAC ducts, plumbing lines, and IT cabling. Therefore, buildings arrive on-site nearly complete, which saves weeks of installation time.

3. Insulation and Paneling

Next, teams add insulation, fire-rated panels, and moisture barriers. These components protect against heat and noise, making modular buildings ideal for offices, residential units, and industrial facilities.

4. Interior Finishing

Finally, modules are fitted with flooring, ceiling tiles, lighting, cabinetry, and décor. This step elevates the building’s look and feel, giving it a premium finish.

Why Steel Fabrication Companies UAE Elevate Modular Construction

Leading steel fabrication companies UAE support modular construction with high-strength beams, platforms, walkways, mezzanines, and support frames. Their products enhance building safety and load capacity. Moreover, steel fabricators supply components for warehouses, power plants, oil and gas sites, and commercial towers.

These companies follow strict international codes. Therefore, the steel structures used in modular buildings are durable, efficient, and future-ready.

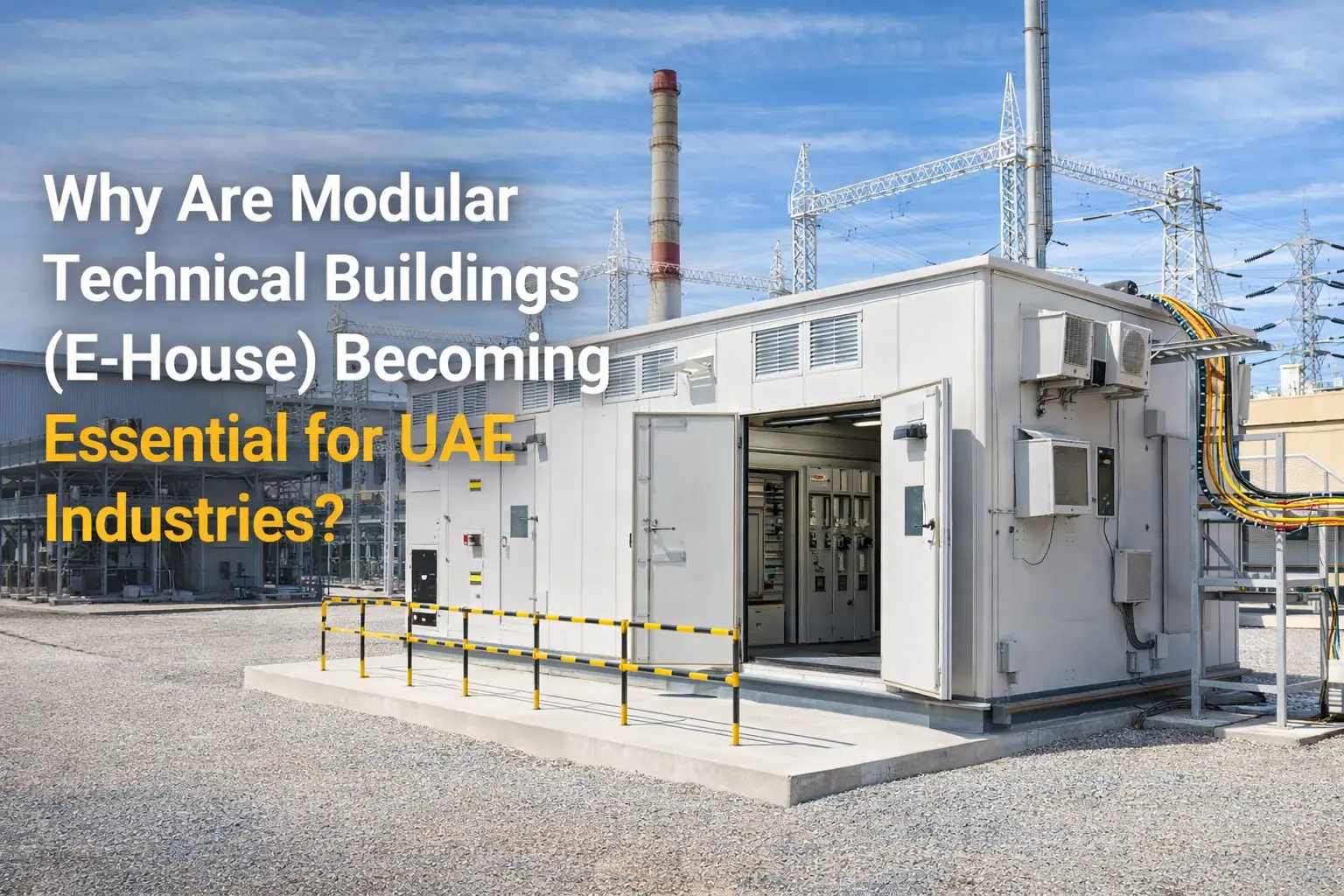

Modular Technical Buildings in the UAE: Built for Critical Environments

The demand for modular technical buildings in the UAE continues to rise. These buildings serve telecom stations, data centers, substations, control rooms, and power distribution facilities. Furthermore, they must operate in harsh desert environments. As a result, they include fire-rated walls, blast-resistant panels, and advanced climate control.

These structures offer unmatched safety and speed. They can be relocated or expanded with minimal downtime, which makes them ideal for energy and infrastructure projects.

Delivery and On-Site Assembly: Faster Than Traditional Construction

Once modules are complete, they are transported to the project location. Cranes position each section on a prepared foundation. Then, installers connect utilities, secure frames, and finalize interior joints.

This entire process is 50–70% faster than traditional construction. Additionally, modular building sites stay cleaner, safer, and less disruptive.

Modular Buildings vs. Traditional Construction: What’s the Difference?

Modular construction offers key advantages:

- Speed: Factories build multiple modules at once.

- Quality Control: Indoor production protects materials from the weather.

- Cost Savings: Faster timelines reduce labor and overhead.

- Sustainability: Less waste and fewer site disruptions.

- Flexibility: Buildings can expand or relocate easily.

Traditional construction still serves complex architectural designs. However, modular buildings excel when projects demand speed, durability, and predictable costs.

Conclusion

A reliable modular buildings manufacturer in the UAE does more than build structures. It delivers speed, strength, and long-term value. When combined with advanced structural steel fabricators in the UAE, steel fabrication companies in the UAE, and premium modular technical buildings in the UAE, the result is a construction ecosystem built for the future.

Today, modular buildings stand as a symbol of the UAE’s focus on innovation, performance, and world-class engineering.

Transform your projects with BERG Industries, a leading modular buildings manufacturer in the UAE. Contact us today for premium modular buildings and steel structures delivered quickly and precisely.

FAQs

What industries use modular technical buildings in the UAE?

Energy, telecom, data centers, oil and gas, and infrastructure companies rely on modular technical buildings. These structures support critical operations and withstand harsh desert environments.

Why choose steel fabricators for modular construction?

Steel fabricators provide strong structural components that support heavy loads. Their precision-engineered steel frames enhance safety, accuracy, and overall building performance.

Are modular buildings durable enough for the UAE weather?

Yes, modular buildings are engineered with insulated panels and corrosion-resistant steel. These materials protect the structure from heat, humidity, and sand, ensuring long-term durability.

Can modular buildings be expanded or relocated in the UAE?

Yes, modular buildings are designed for flexibility. They can be easily expanded, reconfigured, or relocated without major construction, making them ideal for growing businesses and changing project needs.